Experiments in Wadding

In the last year, I’ve had a lot of trouble with pieces sticking in the kiln and sometimes breaking badly. This began when I started experimenting with underglazing the bottoms of my pieces. I did discover that Amaco Velvet underglazes work better than Speedball for this overall, and all underglaze is more successful at cone 5 than cone 6. Another factor was the behavior of slip in the kiln, but I’ll save that for another post. This is all to say that the troubles I had led to experiments in high fire stilting. Commercial wire stilts work well and even allow me to glaze the bottoms of pieces. They also are very sharp, and I stabbed myself badly enough removing them that I don’t think they will be my primary means of stilting. This leads me to wadding.

Wadding is most commonly used in salt, soda, and wood firing. It’s not usually a part of firing in an electric kiln, and I had never heard anyone in my ceramic circle talk about it. So it was a mystery to me. After some research, I decided to try two different recipes. The first is the typical alumina wadding that you can find lots of information about. The second was a rarer calcium carbonate wadding that apparently was meant to mimic the old school use of shells in stilting ware.

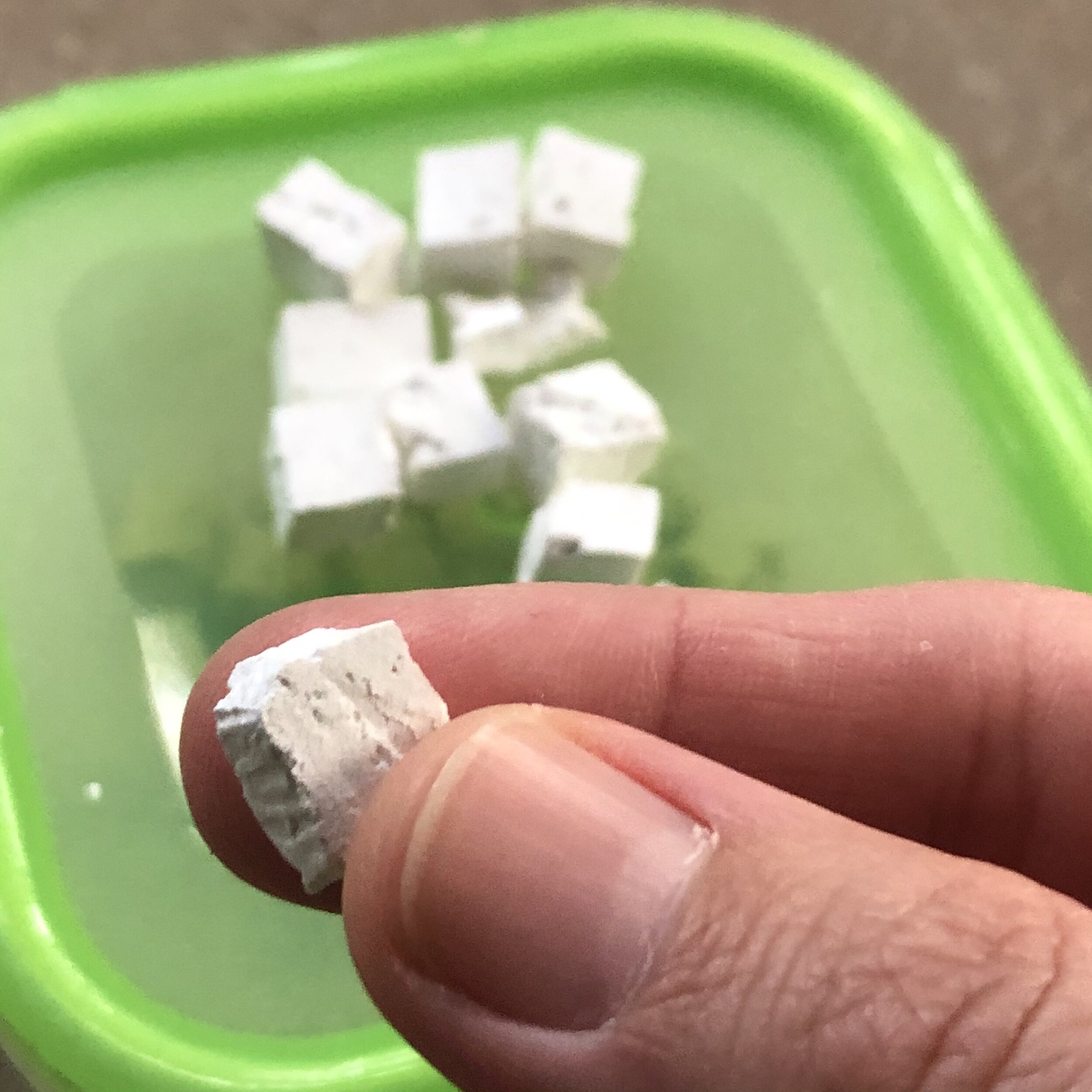

The alumina wadding is made by mixing half alumina, half EPK, plus water. I rolled out the gloppy mix and cut it into cubes that I let dry thoroughly. Then when I was ready to use it, I glued the cubes to the bottoms of the pieces I was firing. It worked great. The wadding looked fired, but otherwise are in good shape. So I wondered if I could just reuse the pieces again.

The calcium carbonate wadding was made by mixing half and half calcium carbonate and plaster to water. I had to guess about the amount of water, so I put the amount for plaster, plus 35% of the weight of the calcium carbonate. It worked pretty well, but was maybe a bit thick for pouring into my mold. One of the great advantages of this method is that you can cast it into any stilt shape you want. I used a silicone mold meant for making chocolate chips. Pointy and sturdy.

I know what you are thinking (because I was thinking it too!). You are wondering about why I would put plaster in the kiln when it is well known that one of the problems with using plaster bats is getting unwanted plaster bits in your clay that cause problems in the kiln. And why would I use this when the alumina wadding worked so well? I tried it because of the apparent advantage of not leaving white marks the way alumina can.